Siemens SGT 400 DLE, 12 MW Generator drive package for sale

Siemens SGT 400 DLE, 12 MW Generator drive package for sale

Location:Poeldijk, Netherlands

Description

Date operational: Dec 2017 to March 2019

Operating hours: 5171

Starts: 71

General information:

Power rating 12 MW

Generator drive, 11 Kv, 50 Hz

Allen Bradley Control system

Natural gas fired

Outdoor package

Detailed information:

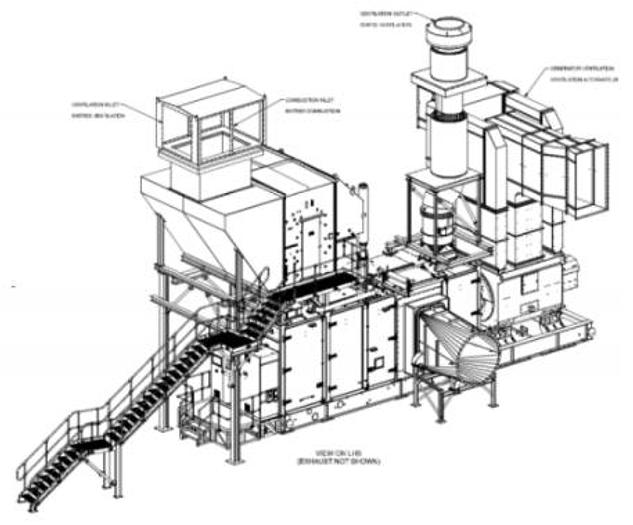

Siemens SGT400, (12,9MW) Gas Turbine package:

Natural gas fired

DLE Combustion

Twin shaft engine

Left hand exhaust

Reduction Gear:

Epicyclic reduciton gear

Baseplate mounted

Hydraulic start drive

Main drive coupling

A.C. Generator and AVR:

11.0 kV, +/- 10%, 3 phase, 50 Hz, 1500 rpm

-0,35 to + 0,4 power factor

Class F insulation and class B total temperature rises

Voltage transformers – class 0,5, current transformers – Class 0,2 and 5P10

Integral Lub Oil System:

Supplies gas turbine, reduction gear and A.C. generator

Priming and main oil pumps

A.C. auxiliary pump

D.C. emergency pump

Lub oil vent oil mist eliminator

Gas fuel system:

Double block and bleed valves and rigid pipework

Fuel control valves (pilot and main)

External block and vent valves

Electro – HydraulicGas Turbine Start System:

400V electric motor

Hydraulic pump and motor

Control valves

Dual Mode Compressor Wash System:

To allow for ‘cranked / off line’ washing

High pressure compressed air wash module

Control valves and pipework

Quick-disconnect connector at skid edge

Mobile tank

Low ambient air temperatures protection

Outdoor Acoustic Enclosure 80dB(A):

Standard colour RAL 7032

Access doors, apertures, gland plates

Interior lighting and inspection windows

Removable panels for alternator removal

Turbine exhaust shroud

Enclosure Vent System 80 dB(A):

Vent system for gas turbine / reduction gear

1-stage static filters (M5)

Negative pressure enclosure

ATEX extraction fan (Zone 1 Exd Gr IIB T3)

Attenuators

Weather protection

Turbine Air Intake System 80dB(A):

Rain / snow ingress protection

Heated vane separator anti icing system

2 stage static air filtration:

1st stage panel filters (M5)

2nd stage panel filters (E11)

Attenuation, ductwork and compensator

Support steelwork

Air Inlet Filter Access Platform:

Ladders

Handrails

Kick plates

A.C. Genrator Vent System 80dB(A):

2 stage static filters (F5 & F8)

Attenuation and compensator

Oil Cooler air Blast System 80dB(A):

Single Axial flow fan

Cooler matrix

Attenuation

Control Cabin:

Houses unit control panel suite and CO2 extinguishant

Interior lighting

Air conditioned

Exhaust System:

Side exit

Primary compensator

Thermal / acousting shroud

Fire Protection and Gas Detection Systems:

Four zone fire monitoring equipment

CO2 storage and CO2 discharge nozzles

Infra-red (3) and heat (rate/rise) detectors (2)

Shut off damper at ventilation system discharge

Two-level gas detection

EN54 / ISO6183 compliant

On-Skid Control Panels:

Comprising of the following:

Gas Turbine Control and Protection Section

Allen Bradley “Controllogix” plc

Digital engine management system

Off-skid remote PC for client interface and control

Control, monitoring and protection (pressures, temperatures, vibration etc.)

Remote communication

System graphics

On-skid HMI

Modular distributed I/O

Data communication link (Modbus protocol over TCP/IP

Motor Control Centre:

Single 400V, 50Hz, 3ph connection

A.C. power distribution for the generator set

Motor starters and protection

Distribution MCB’s for auxialiary a.c. supplies

Skid-mounted allowing a single point of contract for the customer

Battery Charger annd Uninterruptible Power Supply:

Battery chargern and UPS 24Vdc supply to control system

Power to lube oil pump for 3 hours after loss of a.c. supply

Maintenance free batteries

Generator Control and Protection Section:

Electronic Automated Voltage Regulator

Digital integrated Protection Relay, comprising:

Differential fault (87G/T)

Stator Earth Fault (51N)

Overcurrent (51)

Three phase over voltage (59)

Three phase under voltage (27)

Reverse Power (32)

Underfrequency (81U)

Overfrequency (81O)

Loss of excitation (40)

Negative Phase Sequence (46)

Synchronisation Equipment:

Auto and check synchronisers

Selector switeches, bus voltmeter and synchroscope

Automatic or manual forwar and back synchronising

MW circuit breaker control

Medium Voltage Switchgear Cubicles:

11 kV Merlin Gerin Cubicles with:

Couplling breaker

Busbar breaker

Auxiliaries’ transformer breaker

Voltage transformers

High Voltage Sub Station:

90 kV substation with:

65MVA 11kV/90kV transformer

90kV line breaker

Voltage / Current transformers

Exhaust Gas Divertor:

Regulating diverter (pneumatic) with sealing air fan motors.

Heat Recovery Boiler:

Steam production @ 90 t/hr – 18 bar

Burners fro fresh air capability and supplementary firing.

The boiler and gas turbine can be installed and / or operated fully independent of each other.

Gas Station for Turbine and Boiler:

Safety valves

Oil Separator and gas filters

Gas heater

Gas flow meters.

Specifications

| Manufacturer | Siemens |

| Model | SGT400 DLE |

| Year | 2017 |

| Condition | Used |